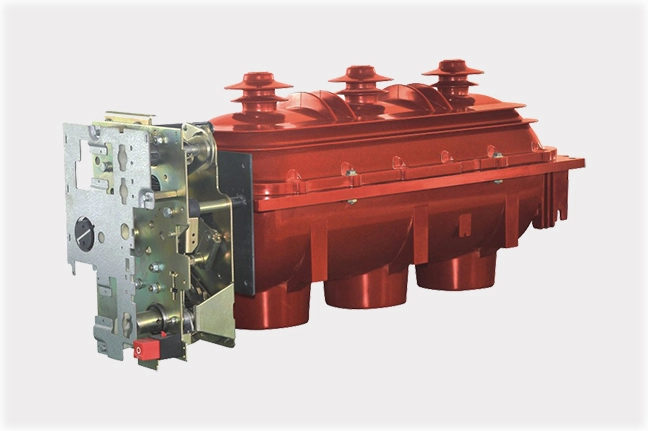

A Load Break Switch (LBS) is a type of switchgear designed to safely interrupt the current flow in an electrical circuit under normal operating conditions, typically during load switching. Unlike Vacuum Circuit Breakers (VCB) or Gas Circuit Breakers (GCB), which can handle short-circuit currents, a Load Break Switch is primarily used for switching load currents—i.e., normal current flow under non-fault conditions.

LBS devices are essential in medium-voltage distribution networks, especially in secondary distribution systems where fault clearing capabilities are not required, and the emphasis is on routine load switching.

The LBS works by using specialized components to ensure the switch can interrupt current safely. These can include arcing horns, spring actuators, and interrupter mechanisms like vacuum or SF6 interrupters, designed to safely manage the arc produced when switching the load current.

Some load break switches, particularly those designed for specific applications, are equipped with features that allow them to handle capacitive or inductive loads and provide a higher mechanical and electrical life, usually up to 5000 mechanical operations and 1000 electrical operations, depending on the type.

Uni offers different types of LBS, including SF6 gas-insulated, vacuum, and air-type load break switches, each suited to different environmental and operational conditions.

How Does a Load Break Switch Work?

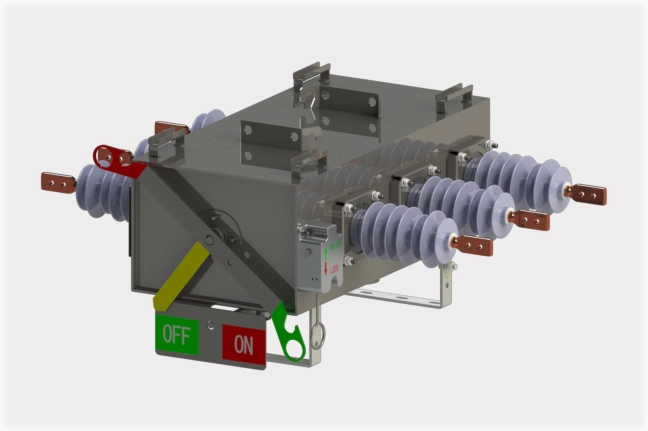

An LBS is essentially a disconnect switch that, with the right modifications, can interrupt specified load currents safely. These modifications might include:

- Arcing horns: A simple, passive method to dissipate the arc energy when the switch is opened.

- Spring actuators: These increase the speed at which the switch blade moves, allowing the current to be interrupted more efficiently.

- Vacuum or SF6 interrupters: More advanced interrupters used to deal with high-voltage applications and ensure the arc is extinguished quickly when the switch opens.

An LBS, when designed for medium-voltage networks, helps isolate faulty sections of the network or de-energize equipment during maintenance. They are often used for switching loads such as:

- Capacitive currents: The current that is present due to the charging of cables or transformers when the system is energized.

- Inductive loads: Loads with a magnetic field, like transformers and motors.

In medium-voltage switchboards, the SF6-insulated LBS is commonly used, providing enhanced safety and efficiency in de-energizing the circuit and avoiding equipment damage.

Difference Between Load Break Switch and Circuit Breaker

The primary differences between a Load Break Switch (LBS) and a Circuit Breaker (CB) lie in their breaking capacity and making capacity.

Breaking Capacity:

- A Load Break Switch is onlydesigned to break the current under normal operating conditions. It can switch on/off load currents but is not capable of interrupting fault currents (i.e., short circuits).

- A Circuit Breaker, on the other hand, is designed to make and break both load and fault currents. It can clear fault conditions and safely disconnect sections of a network during abnormal conditions, like short circuits or overloads.

Making Capacity:

- The making capacityrefers to the ability of the switchgear to withstand the initial inrush current or fault currents when the switch is first closed. The making current can be higher due to initial transients, such as inrush currents when transformers are energized or long transmission lines are energized.

- A Load Break Switch does not have a making capacity. It is designed to close and open only under loadconditions, and typically should not be closed on a fault.

- A Circuit Breaker, however, is capable of closing onto a fault (making rating) and clearing the fault after the current has been interrupted (breaking rating).

Key Differences

| Feature | Load Break Switch (LBS) | Circuit Breaker (CB) |

| Function | Switches normal load currents | Makes and breaks both load and fault currents |

| Breaking Capacity | Limited, designed only for load currents | Designed to break fault currents |

| Making Capacity | Does not have making capacity | Can close onto a fault (making capacity) |

| Operation Conditions | Designed to operate under normal conditions only | Designed to operate in both normal and fault conditions |

| Application | Used to isolate or connect healthy circuits, load switching | Used to clear faults, protect equipment from short-circuits |

| Cost & Complexity | Less expensive, simpler design | More expensive, complex with fault protection |

Important Considerations for Using Load Break Switches

While the LBS is highly useful for load switching, there are limitations to its use. These switches are not recommended for switching fault currents or circuits with high inrush or capacitive current, such as:

- Long cables: These can have high charging currents, which an LBS may struggle to interrupt.

- Large transformers: Switching these with an LBS can lead to undesirable inrush currents.

- Reactive loads: High inductive loads or large motors can also produce currents that LBS is not designed to handle.

In such cases, a Circuit Breaker is recommended as it can safely interrupt fault currents and handle inrush currents.

A Load Break Switch (LBS) plays a vital role in medium-voltage electrical distribution networks. It allows for safe and efficient load switching under normal conditions, providing a way to de-energize or energize equipment. However, due to its limited breaking capacity, it is essential to understand the application limits and the specific scenarios in which an LBS can be used effectively.

For higher-current interrupting and fault-clearing applications, Circuit Breakers (CBs) are necessary. As a precaution, LBSs should only be used in situations where the equipment is not under load or where fault currents are not present.

By understanding the distinctions between these two types of switchgear, electrical engineers and operators can ensure the right choice of equipment for both operational efficiency and equipment protection.

A load break switch is a disconnect switch that has been designed to provide making or breaking of specified currents. This is accomplished by addition of equipment that increases the operating speed of the disconnect switch blade and the addition of some type of equipment to alter the arcing phenomena and allow the safe interruption of the arc resulting when switching load currents. SF6 Insulated Load Break Switch for the use in medium voltage switchboards for secondary distribution networks.

Disconnect switches can be supplied with equipment to provide a limited load switching capability. Arcing horns, whips, and spring actuators are typical at lower voltages. These switches are used to de-energize or energize a circuit that possesses some limited amount of magnetic or capacitive current, such as transformer exciting current or line charging currents.

An air switch can be modified to include a series interrupter (typically vacuum or SF6) for higher voltage and current interrupting levels. These interrupters increase the load break capability of the disconnect switch and can be applied for switching load or fault currents of the associated equipment.

Accordingly, the Circuit breakers have both while the Isolator or LBS has only breaking capacity. Isolator therefore used to isolate/disconnect/break load. To be switched on only under no load.