H-Class lmpregnated Insulated Dry-type Transformer

H-Class lmpregnated Insulated Dry-type Transformer

Applications:

Urban Areas

Power Distribution

Heavy Industry

Railway Stations and Airports

Application

This H-Class Impregnated Insulated Dry-type Transformer is a type of dry-type transformer designed for high-temperature applications and enhanced insulation performance.

- High Thermal Endurance: The Class H insulation and impregnation process make the transformer capable of operating in environments with elevated temperatures and higher electrical load.

- No Risk of Oil Leakage: Since there is no oil used in the cooling or insulation, the risk of oil leakage and the associated fire hazards is eliminated.

- Lower Maintenance Requirements: The dry-type design and impregnated insulation materials generally require less maintenance over time.

- Environmentally Friendly: The absence of oil makes dry-type transformers more environmentally friendly as they eliminate the need for oil handling and disposal.

- Reduced Fire Hazard: They are safer in terms of fire risk due to the absence of flammable liquids.

Specifications

Insulation

- Class H insulation refers to the maximum temperature rating of the transformer’s insulating materials. This class can withstand temperatures up to 180°C (356°F). In comparison, other insulation classes like Class F and Class B have lower temperature ratings, making Class H transformers suitable for more demanding environments where higher thermal tolerance is required.

- Impregnated insulation involves the use of insulating resin that is impregnated into the windings and core. This process helps enhance the insulation properties and prevents moisture and contaminants from affecting the transformer’s performance. The impregnation process ensures high electrical resistance, better thermal dissipation, and greater overall reliability.

Impregnation Process

- The windings and core are soaked in an insulating resin (often epoxy or polyester-based) under vacuum or pressure. This process enhances the mechanical strength and dielectric properties of the transformer.

- This impregnation method helps to prevent the formation of air gaps, improving the reliability and efficiency of the transformer, especially in high-load applications.

Maintenance:

- These transformers are low-maintenance compared to oil-filled ones because they don’t require regular oil checks or replacements. However, they still need to be inspected periodically for dust, dirt, and any signs of damage to the insulation.

Parameter

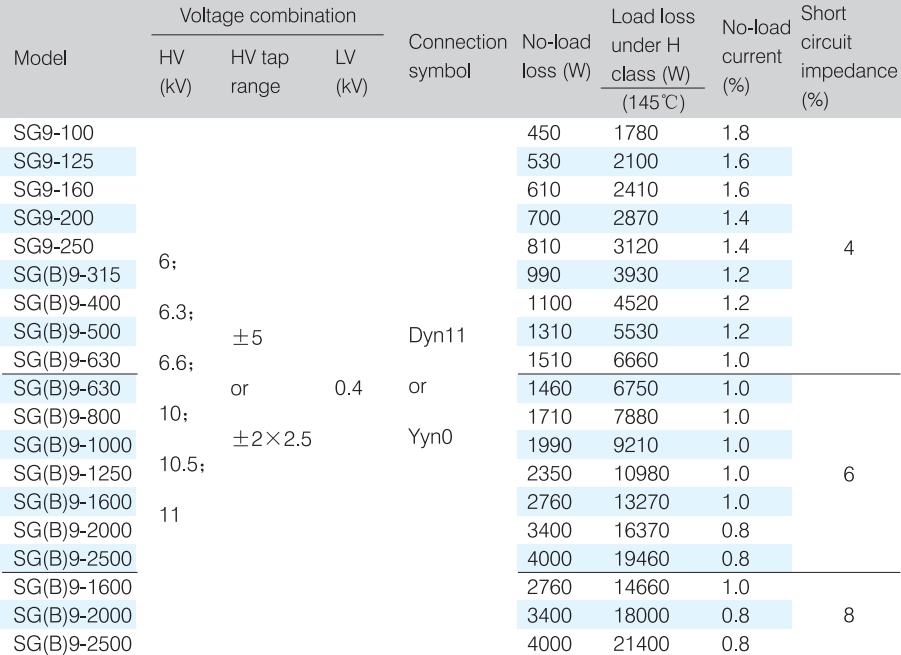

9 Series 10kV Free Excitation Voltage Regulation Distribution Transformer

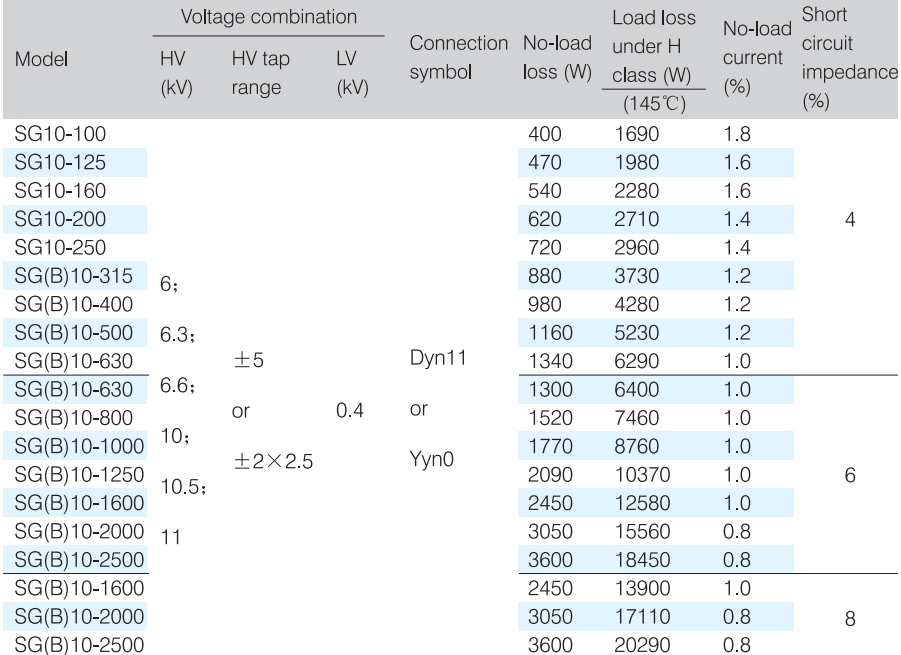

10 Series 10kV Free Excitation Voltage Regulation Distribution Transformer

PDF Download

PDF Download

Why Choose Us

Contact Us Immediately

Contact Us

- 24-hour online service

- Own factory processing

Product Category

hot-sale product

Series: SCB12

Application: Distribution Transformer

Country of Origin: China

Certifications: ISO9001, CB, CE, KEMA

Primary Voltage:11KV

Secondary Voltage:0.33KV

Power Rating: 1000 KVA

Connection Type: Dyn11/Yyno or others

Transformer Type: Dry Type Transformer

Standards: ANSI/IEEE, CSA/CAN, DOE

Certificate: UL, cUL, CSA, SGS,CE

QZ Group Co., Ltd. delivers top-tier electrical equipment and solutions to meet your needs. With a robust portfolio of products and a commitment to excellence, we are your trusted partner in the electrical industry.

Follow Us:

products

Inquiry

© Copyright 2024 by QZ Group Co., Ltd. All Rights Reserved.