Project Background

In South Africa, there is an increasing demand for reliable and efficient electrical power, especially in heavy industries such as mining, manufacturing, and infrastructure development. A large-scale manufacturing plant in the industrial region of South Africa required a high-capacity transformer to support the operation of its machinery and systems. The plant’s power needs were substantial, with heavy-duty equipment requiring a stable and efficient power supply. The company selected a 1600 KVA 11(6.6)/0.42 KV Step-Down Dry-Type Transformer to meet these demands while adhering to strict safety and environmental standards.

Performance Results

- Stable Power Supply: The transformer has provided a reliable and continuous power supply to the plant, supporting the operation of heavy-duty machinery, lighting, and other critical systems. It has demonstrated stable performance under full-load conditions without any significant interruptions or downtime.

- Energy Efficiency: The plant has reported a noticeable reduction in energy costs, thanks to the transformer’s high efficiency. The low energy losses during operation have translated into lower overall operating costs, helping the plant improve its profitability.

- Safety and Low Maintenance: As a dry-type transformer, it has eliminated the risk of oil leaks and fire hazards, significantly improving safety at the plant. Furthermore, the transformer requires minimal maintenance, leading to reduced downtime and lower maintenance costs.

- Environmental Durability: The transformer has operated seamlessly in South Africa’s challenging environmental conditions, including high temperatures and dusty conditions, demonstrating its durability and resilience. The advanced insulation and dry-type design have protected the transformer from the harsh elements.

Product Introduction

Two units 1600 kVA epoxy resin cast dry type transformers were delivered to South Africa in 2023 August.

The rated power of the dry type transformer is 1600 kVA with AN/AF cooling, the primary have two voltages which are 11 and 6.6 kV with ±2*2.5% tapping range (NLTC), the secondary voltage is 0.42 kV, they formed a vector group of Yyn0 for 11kV and Dyn11 for 6.6kV. The HV and LV cables are top entry, an 800 * 400mm opening is provided on the top of the enclosure for HV cable incoming, an 400*400mm opening is provided on the top of enclosure for LV cable incoming. Which is sealed with temporary low-carbon steel plate. The shock proof rubber pad is installed at the top of the transformer, which has excellent isolation effect and can reduce the impact of live load and seismic force on the transformer. There are three surge arresters installed on the enclosure and connected to the each phase of HV terminal.

Cast resin technology provides excellent insulation and environmental protection, this together with the foil winding technology inside the resin offers the ultimate dry type transformer in terms of dielectric performance and short circuit withstand ability and ensures long term reliability for both distribution and special applications. cast resin transformers can be supplied with either aluminum or copper windings together with possibility of class F or class H insulation system, they can be designed to in-door or out-door installation with different enclosures.

We ensure that each one of our delivered units has undergone rigorous full acceptance testing. We provide one-package service from consulting, quoting, manufacturing, installation, commissioning, training to after sale services, our products are now operating in more than 50 counties in the world. We aim to be your most reliable supplier as well as your best partner in business!

Advantages

Fire resistant /Self-extinguishing(F1)

Environmental class(E2) and climatic class (C2)

From IP00-IP56 enclosure with AN, AF, ANAF or AFWF cooling

Maintenance free

Environmental friendly ,>90% of material recyclable

Temperature control system

Built-in PT100 probes in 3 phase windings to detect the real-time temperature of windings and cycle display them in the digital screen.

Open circuit alarm and fault self-check alarm display and signal output.

3 stages automatically actions while the temperature reached to the set value, 1st stage the cooling fans start automatically, 2nd stage high temperature alarm,3rd stage over temperature trip.

Fans manual/auto control switch, timing start/stop, history data output.

4-20mA current output

RS485 Modbus communication protocol

Environment temperature measurement

Core temperature measurement

Scope of Supply

Product: resin cast dry type transformer

Voltage level: up to 35KV

Rating level: up to 20MVA

The transformer can be designed according to customer’s requirements

Technical Data Sheet

1600 KVA Dry Type Transformer specifications and data sheet

| Delivered to | South Africa |

| Year | 2023 |

| Model | SCB-1600kVA-11(6.6)/0.42kV |

| Type | Resin cast dry type transformer |

| Standard | IEC60076 |

| Rated Power | 1600 kVA |

| Frequency | 50 HZ |

| Phase | Three |

| Cooling Type | AN/AF |

| Primary Voltage | 11(6.6) kV |

| Secondary Voltage | 0.42 kV |

| Winding Material | Aluminum |

| Vector Group | Yyn0&Dyn11 |

| Impedance | 6% or above |

| Tap Changer | NLTC |

| Tapping Range | ±2*2.5% |

| No Load Loss | 2450 W |

| On Load Loss | 13000 KW |

| Accessories | Temperature controller, Cooling fans, Enclosure, Skids, lifting lugs & pulling eyes, surge arrester, UPS/VSDs/LED Lighting/Controls,Rubber supports for anti vibration |

| Remarks | N/A |

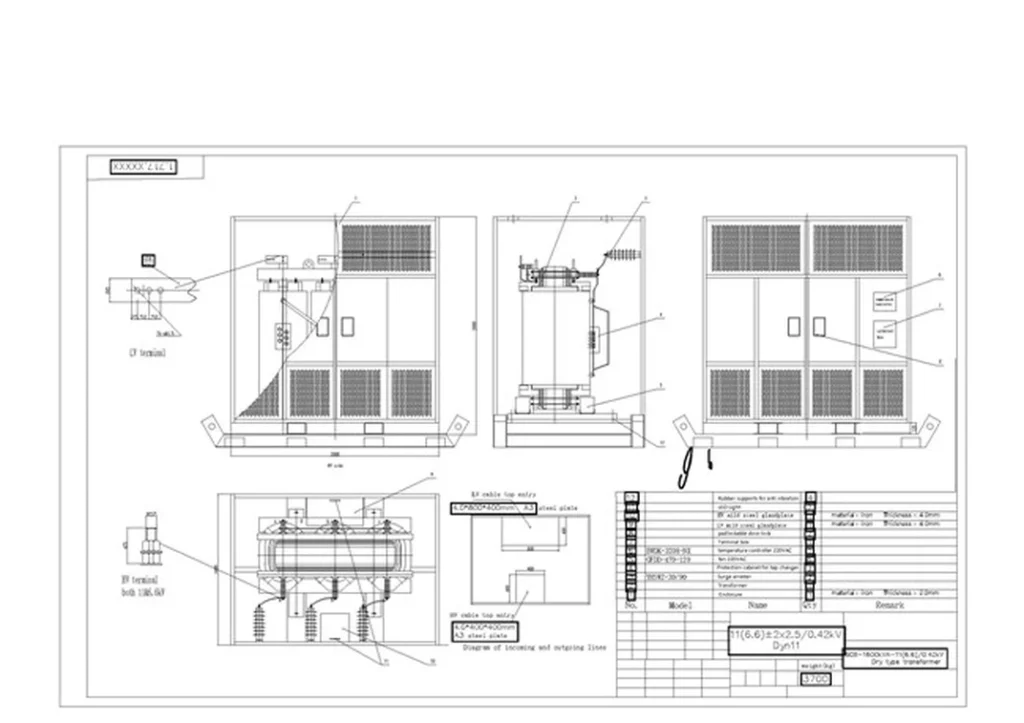

1600kVA-11(6.6)/0.42kV Transformer Drawing

1600 kVA transformer diagram drawing and size.

Transformer Enclosure

Packing and Delivery